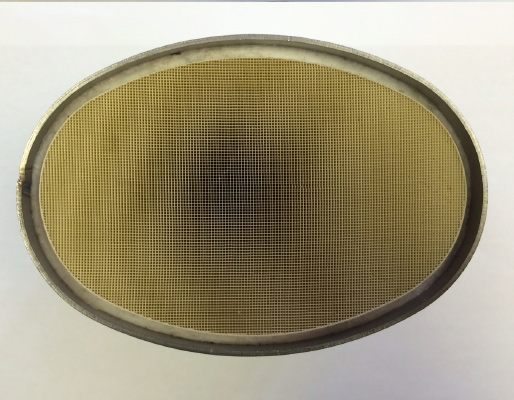

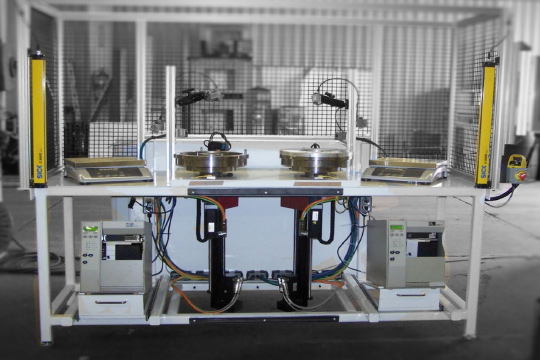

Brick & Mat Measuring Station

GWS has a large selection of Brick and Mat Measuring stations to suit any of your canning needs. This station will measure the perimeter of the bricks and the weight of the mat.

Catalytic Converter Manual Forming Equipment

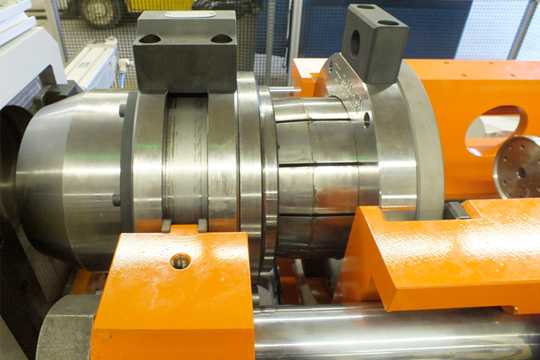

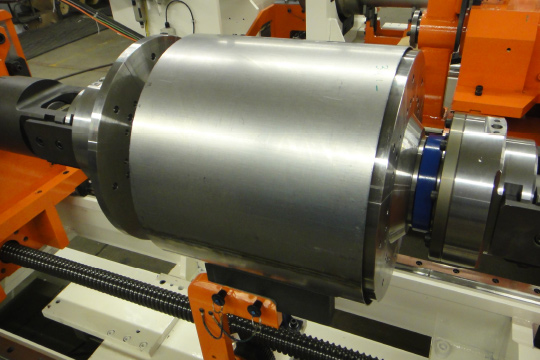

GBD Sizing Machine

GWS Sizing Machines come in many different sizes allowing for the forming of a variety of parts. The sizing tools are designed to either reduce or expand the parts to a calculated GBD.

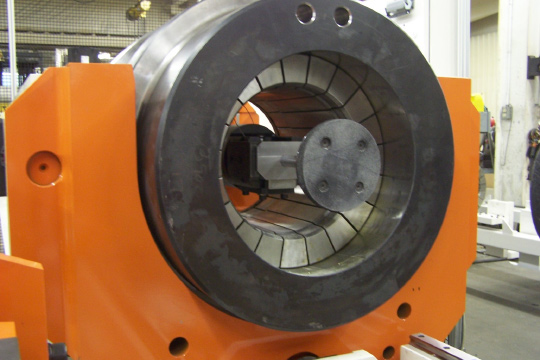

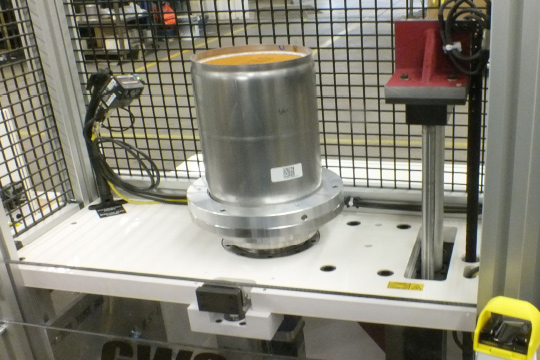

GBD Inspection Station

GWS Inspection stations are used to measure the outside perimeter of sized part. The station will inspect the part to ensure the correct GBD has been achieved for the stuffed components.

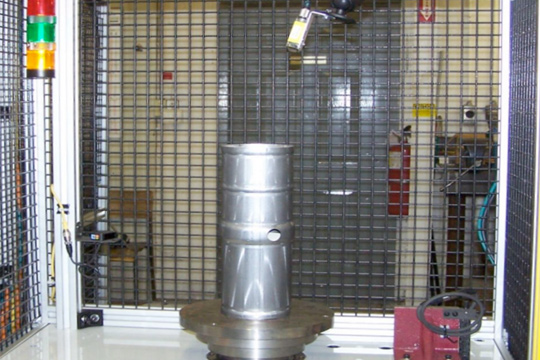

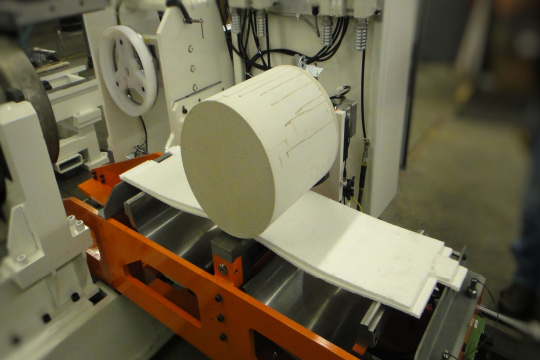

Autowrap Stuffing

Autowrap Stuffing machines that are equipped within a Manual Canning line are loaded by an operator. Once loaded the mat is automatically wrapped around the brick and stuffed into the shell.

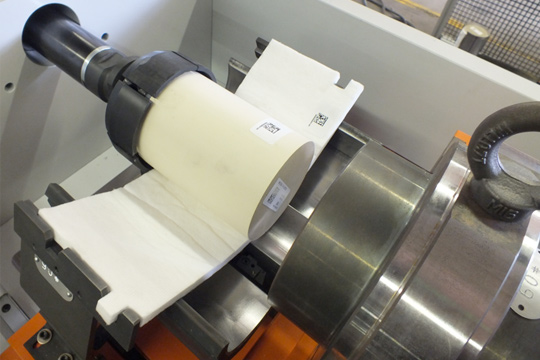

End-Cone Interface Sizing

GWS manufactures a variety of End-Cone Sizing machines which are used to size only the end-cone interface onto a part.

Part Marking Station

Part Marking Station’s are used to mark identification information onto the shell. GWS uses a selection of scribing machines, part markers and laser engravers to mark the desired information onto the part.

Catalytic Converter Automatic/Semi/Automatic Forming Equipment

We produce both pre and post size catalytic converter forming cells for both.

Brick & Mat Measuring Station

GWS has a large selection of Brick and Mat Measuring stations to suit any of your canning needs. This station will measure the perimeter of the bricks and the weight of the mat.

Autowrap Stuffing

Autowrap Stuffing machines are used to automatically wrap the mat around the substrate. Automating this process allows for quicker and more accurate stuffing results.

Automatic Part Positioning

Automatic Part Positioning is used to move and position the part in and out of the forming tooling. This allows the sizing position on the part to be located very accurately.

GBD Sizing Machine

GWS Sizing Machines come in many different sizes allowing for the forming of a variety of parts. The sizing tools are designed to either reduce or expand the parts to a calculated GBD.

Automatic Part Transfer

Part Transfers are used in GWS Automatic & Semi-Automatic Forming cell’s to transfer the parts to each station.

GBD Inspection Station

GWS Inspection stations are used to measure the outside perimeter of sized part. The station will inspect the part to ensure the correct GBD has been achieved for the stuffed components.

GWS System Overview

- Complete lot traceability & Poke Yoke of ALL Components

- Measure and Weigh bricks/mats

- Integrated automatic wrapping, stuffing & GBD Sizing

- GBD Inspection and end-cap size verification

- Sizing of all three maximum GBD Zones

- All Data recorded to MS SQL Database

- Rounds, Ovals & Other Shapes

- Flexible volume cell’s

- Full Automated Cell’s

- Robot Integration available

- 200,300 & 400mm Machine capabilities